-

Posts

2,708 -

Joined

-

Last visited

-

Days Won

131

Content Type

Forums

AutoShopOwner Articles

Downloads

Blogs

Gallery

Profiles

Events

Store

Links Directory

Shop Labor Rates

Community Map

Everything posted by Gonzo

-

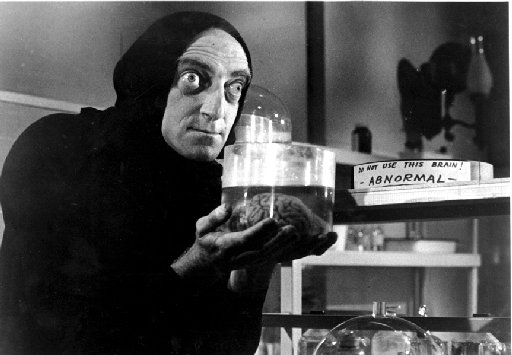

Brain Damage - - - "How many brains does it take to fix a car?"

Gonzo posted a article in Gonzo's Tool Box

Brain Damage Throughout the evaluation of the modern car there have been an increasing number of duties taken over by computers. These computers have not only made the engine more fuel efficient, but also more environmentally friendly. Nowadays, these systems are starting to think for themselves and make decisions for the driver. Things like parking the car, keeping a safe distance from the car in front of you, or avoiding accidents are just a small part of the capabilities of the modern computer driven automobile. In some ways the car has become a thinking, reasoning, and quite capable robotic apparatus. You're not sure of that? Really? Let's define robotic function and a robot's task. A robot is a device that manipulates its surroundings by way of certain inputs, which are dictated by the software or information instructions set into its protocol. In a sense the information in its brain. Not all "robots" are in a form of the walking, talking version; a robot can be stationary and perform one task over and over again. Take for example ABS (Anti-lock Brake System). This can be considered a robotic function. The ABS module (or brain) is given a task by way of its programming, and in turn watches for certain input signals from various sources such as the wheel speed sensors, brake pedal application, and engine and transmission inputs. It's a stationary robot in a non-stationary setting. If the system fails to follow the preset instructions it gives the human an indication of its condition by way of a service light. The repair needed is still left up to the technician. I'm kind of glad for that, as I don't know if I'm up to dealing with the "Terminator" mentality of a walking, talking robotic device that inevitability figures out it's smarter than its creator. These days a modern technician uses a computer to talk to the vehicle's computer. That makes it three "brains" involved in determining the reason for the service light: two cyber brains and one human brain. Each one of them has to do their job correctly. When one or more of these "brains" malfunctions, (and yes, I do mean the technician's too.), the whole process of figuring out the problem becomes a lesson in futility. I recently had a car in the shop that wasn't communicating with any of my scanners. As the technician, aka "The Human Brain", it was my task to figure out why and where the lack of communication was emanating from. It wasn't long before I tracked down the culprit. Not only was the main PCM in the car dead, but so were several other processors as well. Looks like a case of brain damage to me. All the usual suspects for this type of problem, such as powers, grounds and communication lines checked out to be in good condition. The test results showed that the car had been struck by lightning. Looks like this little robotic wonder of modern technology had been done in by Mother Nature herself. Even in the electronic age…Mother Nature still rules. But among the variations of problems a technician can run across there are those occasions where the car is fine, but its second brain (the "scanner") is damaged in some way. On occasions I've had to deal with an uncooperative scanner. After countless times of getting in and out of a car, the endless twisting and manipulating of the cords and connections, the scanner can come down with its own form of brain damage. Sometimes it's the service cord at fault, and other times it's the scanner itself. (I keep the shipping boxes just in case I have to send one in for repair.) The big problem for the consumer these days is the modern car can't function without these computers, nor can the modern technician diagnose or repair a lot of the functions without a computer to talk to the car. We've become so dependent on the electronic wizardry of these modern conveniences that our world today couldn't function as we know it without them. Sometimes I feel like I've got brain damage myself when I'm trying to figure out the multitude of problems brought on by all these electronic components. There are many numerous problems that only exist in today's cars because of all these technical advancements. You wouldn't see some of these problems in a car without a computer under the hood. In years past a lot of car components were rebuilt right in the shop,and most everything was a "hands-on" repair. A mechanic removed a part, and would take it down to its individual components, then replace one or more parts of the original component and reassemble it. Not so today; most parts are electronic or have been manufactured in a way that the individual parts can't be taken apart. A good example of this is the HVAC systems. It used to be cables and levers that operated the doors and temperature flow. Nowadays, it's sensors, drive motors and processors. Computers and these robotic functions have literally taken over our everyday life right down to the point of turning on the A/C in the car. You're not moving a lever or turning on the compressor, instead you're asking permission from the computer. It determines whether or not all the required systems are functioning properly. If they are…then "it" (the computer) will allow you to have the air conditioning on. You don't decide… the computer decides for you. For the most part, today's automotive repairs require a high degree of understanding of electronics, as well as mechanical aptitude. You really need both to be a good tech these days. The stereotypical view of the local mechanic as some brain damaged, misbegotten youth with a rag sticking out of his pocket is all but gone; he's more of a brain surgeon than a grease monkey these days. Our technical advancements and electronic world is moving closer and closer to a place our forefathers of just one generation ago would never recognize. It won't be long before the automatous car is the norm (which is nothing more than a robot on wheels.) These innovations are enough to give me brain damage if I ever get a chance to stop and think about them long enough. As it has always been in this field… change is constant and dealing with those changes is what the technician has to deal with. I'll admit I do find all these modern conveniences fascinating, as well as totally plausible…they make our lives physically and mentally less stressful, but I gotta draw the line somewhere. Some people like to bike, others like to hunt or fish, while my favorite pastime is golf. I do like using the GPS to show the yardage…but I'm not using a "Terminator" to hit the golf ball for me… Besides… it would probably keep score better than I do anyway. Even in this modern technical world there are still a few things this old, brain damaged tech would rather do without a computer involved. -

lCouldn't leave NASCAR out of the duct tape. Every time i watch a live race i always say, "this race is on tape!" Nobody gets the joke.... lol

-

Thanx... it's on tape... lol

-

DuctTape When people list the millions of uses for duct tape they never seem to include the various ways I've seen it used on the family car. I'm a big fan of duct tape myself. My son has even made himself a handy little wallet, a tie, bookbinders, and whole bunch of other cool things with it. I'm no pro at conjuring up different uses for this stuff, but I've seen what some creative people can do with a roll. Why, just last night I was out to dinner with the family, and low and behold there in the parking lot was a minivan with the front bumper strapped on with layers upon layers of duct tape. Nice job... it definitely was holding it in place, that's for sure. You could tell it's been that way for quite some time, all the edges were starting to fray and the inner grid of the tape was showing through.(Probably time for another layer…) Even NASCAR has found a use for this magical fix all tape. If you're running around the track at high speed and you get tagged by the guy trying to pass you, there's a good chance something is going to get torn off. The next trip around the fourth turn means a little more tug on the steering wheel, and a down shift into the pits. Then your pit crew jumps the wall, slaps on a few layers of duct tape, and off you go back out onto the track again, grabbing the next gear and holding the pedal to the floor. No wonder duct tape has the nickname "200 mph tape". Then there are those uses I think are really ridiculous. Like using duct tape to hold up a broken electric window. It probably sounded good at the time, but wait until you need to take it off. That's usually left up to me when the car is in for repair. It will come off, but you might need a bit of elbow grease and a few shots of cleaner and solvent to get it off. It's even more fun to remove on a hot summer day;it can be an icky, gooey, nasty, slimy mess to get off the paint and windows of the car. Talk about creativity, I've seen duct tape hold broken glove box doors in place, center console lids, visors, door panels, and various other assorted interior components together. I've even had a car come in that had it wrapped around the entire steering wheel, as if it was a steering wheel cover. Not to mention the patched upholstery, a stereo install gone wrong, or the broken key fob. The list is endless. Let's not leave the exterior out of this, there's the trunk lid when the latch has broken, using it as electrical tape, repairing a broken taillight lens, or the occasionally door that won't stay shut. Of course, then there's the engine compartment; it's a plethora of unending duct tape extravaganzas there. You know, if it's all you have at the time, well... I guess you have to use what you've got on hand...but, really... it's "duct tape" not "tape to hold the coat hanger in place where the radio antenna used to be". It gets hysterically funny when you get a chance to really notice what some duct tape connoisseurs have dreamed up in the way of duct tape innovations. Some time ago I had a car come in the shop with a severe drivability problem. The service light was on; it was stalling, hard to start, no power,coughing, and for the most part... just plain sick. The service codes showed a rich condition and some really crazy short fuel trim values. When I opened the hood I noticed the rubber intake plenum was completely collapsed onto itself. I thought that was a bit weird, but I might as well pop it back into shape and see what happens. At first the car sounded great,but in a few seconds it was back to what it was doing. This time I took the plenum off the car and checked it a little further. Wedged up against the filter box opening to the plenum was a huge wad of duct tape, completely strangling the air intake system. Apparently the owner couldn't find the right size air filter for the car, so he used the duct tape to make the opening small enough to accommodate the air filter. It had been on the car for so long he completely forgot about it. As the duct tape adhesion deteriorated, it started to slowly ball up at the connection between the filter box and the leading edge of the plenum. One new (correct) air filter, and a lot less duct tape took care of the problem. I know it's called"duct tape" and this is a duct, but this isn't the kind of duct to be using it on. (I'll have to add this to my list of failed uses for duct tape.) There was a TV program on not long ago that did a whole segment on duct tape. (Had to watch that one for sure.) They turned duct tape into a sail boat, picked a car off the ground with it, and showed several other cool ways of using it. I'll have to admit they were pretty ingenious and proved the point of how versatile this sticky stuff is. I'm sure there are more ideas that haven't been tried yet, and I doubt that we'll ever run out of ideas for using duct tape in some creative way. Who doesn't have a roll of duct tape lying around somewhere, and who hasn't tried some crazy idea with this stuff? Ok, Ok… maybe splicing a car back together wasn't the smartest thing I've ever seen duct tape used for… but it sure was cool. Ah yes, duct tape, it's a good thing to keep around for a variety of emergency repairs. It has a purpose no matter where you are or where you go. I keep a roll handy in my tool box all the time. You never know when the need for a few strips of duct tape will come in handy. Just ask the guys on Apollo 13 how valuable a roll of duct tape was. Yep, that's right duct tape even went to the moon. Duct tape… if it's good enough for NASA, it's good enough for me. View full article

-

DuctTape When people list the millions of uses for duct tape they never seem to include the various ways I've seen it used on the family car. I'm a big fan of duct tape myself. My son has even made himself a handy little wallet, a tie, bookbinders, and whole bunch of other cool things with it. I'm no pro at conjuring up different uses for this stuff, but I've seen what some creative people can do with a roll. Why, just last night I was out to dinner with the family, and low and behold there in the parking lot was a minivan with the front bumper strapped on with layers upon layers of duct tape. Nice job... it definitely was holding it in place, that's for sure. You could tell it's been that way for quite some time, all the edges were starting to fray and the inner grid of the tape was showing through.(Probably time for another layer…) Even NASCAR has found a use for this magical fix all tape. If you're running around the track at high speed and you get tagged by the guy trying to pass you, there's a good chance something is going to get torn off. The next trip around the fourth turn means a little more tug on the steering wheel, and a down shift into the pits. Then your pit crew jumps the wall, slaps on a few layers of duct tape, and off you go back out onto the track again, grabbing the next gear and holding the pedal to the floor. No wonder duct tape has the nickname "200 mph tape". Then there are those uses I think are really ridiculous. Like using duct tape to hold up a broken electric window. It probably sounded good at the time, but wait until you need to take it off. That's usually left up to me when the car is in for repair. It will come off, but you might need a bit of elbow grease and a few shots of cleaner and solvent to get it off. It's even more fun to remove on a hot summer day;it can be an icky, gooey, nasty, slimy mess to get off the paint and windows of the car. Talk about creativity, I've seen duct tape hold broken glove box doors in place, center console lids, visors, door panels, and various other assorted interior components together. I've even had a car come in that had it wrapped around the entire steering wheel, as if it was a steering wheel cover. Not to mention the patched upholstery, a stereo install gone wrong, or the broken key fob. The list is endless. Let's not leave the exterior out of this, there's the trunk lid when the latch has broken, using it as electrical tape, repairing a broken taillight lens, or the occasionally door that won't stay shut. Of course, then there's the engine compartment; it's a plethora of unending duct tape extravaganzas there. You know, if it's all you have at the time, well... I guess you have to use what you've got on hand...but, really... it's "duct tape" not "tape to hold the coat hanger in place where the radio antenna used to be". It gets hysterically funny when you get a chance to really notice what some duct tape connoisseurs have dreamed up in the way of duct tape innovations. Some time ago I had a car come in the shop with a severe drivability problem. The service light was on; it was stalling, hard to start, no power,coughing, and for the most part... just plain sick. The service codes showed a rich condition and some really crazy short fuel trim values. When I opened the hood I noticed the rubber intake plenum was completely collapsed onto itself. I thought that was a bit weird, but I might as well pop it back into shape and see what happens. At first the car sounded great,but in a few seconds it was back to what it was doing. This time I took the plenum off the car and checked it a little further. Wedged up against the filter box opening to the plenum was a huge wad of duct tape, completely strangling the air intake system. Apparently the owner couldn't find the right size air filter for the car, so he used the duct tape to make the opening small enough to accommodate the air filter. It had been on the car for so long he completely forgot about it. As the duct tape adhesion deteriorated, it started to slowly ball up at the connection between the filter box and the leading edge of the plenum. One new (correct) air filter, and a lot less duct tape took care of the problem. I know it's called"duct tape" and this is a duct, but this isn't the kind of duct to be using it on. (I'll have to add this to my list of failed uses for duct tape.) There was a TV program on not long ago that did a whole segment on duct tape. (Had to watch that one for sure.) They turned duct tape into a sail boat, picked a car off the ground with it, and showed several other cool ways of using it. I'll have to admit they were pretty ingenious and proved the point of how versatile this sticky stuff is. I'm sure there are more ideas that haven't been tried yet, and I doubt that we'll ever run out of ideas for using duct tape in some creative way. Who doesn't have a roll of duct tape lying around somewhere, and who hasn't tried some crazy idea with this stuff? Ok, Ok… maybe splicing a car back together wasn't the smartest thing I've ever seen duct tape used for… but it sure was cool. Ah yes, duct tape, it's a good thing to keep around for a variety of emergency repairs. It has a purpose no matter where you are or where you go. I keep a roll handy in my tool box all the time. You never know when the need for a few strips of duct tape will come in handy. Just ask the guys on Apollo 13 how valuable a roll of duct tape was. Yep, that's right duct tape even went to the moon. Duct tape… if it's good enough for NASA, it's good enough for me.

-

there's a story in my book, ("Hey Look, I Found the Loose Nut") that has a similar situation. It was over a transmission that didn't have reverse. You'll have to read the story... it's exactly the same type of a situation. But I like Franks answer... Ya can't fix Stupid... LOL

-

Gary, where were your words of wisdom when I opened my shop? Better late than never, I totally agree with ya... the more you know the better off you are, whether that's repairing cars or running a successful business. You said it!!

-

We've had some construction guys at our house for the past couple of days installing new windows. One of the guys cut his hand on some broken glass. As my wife was putting on a few bandages she handed him this article... LOL... he got a laugh out of it and totally could see how this relates to any type of work. Made my day... LOL

-

Sell the Job, Not Labor TIME and Parts

Gonzo replied to Joe Marconi's topic in AutoShopOwner Articles

Been in this predicament myself. I had a guy that I told up front that I would charge a minimum of a 1/2 hour to look at his car. (This is a long time before a diagnostic charge was ever considered as a part of our routine repairs.) He agreed, and when I found the problem his only response was, "It's only been fifteen minutes!" Needless to say I had the same conversation you had with your customer. Which, ended up with the same results.... I'm a bit ticked off, the customer is a bit ticked off, and even with an adjusted bill... everybody is still ticked off. Here's my resolution for this dilemma. Instead of hours, I quote dollars and then time. I compare it to making a bid on building a bridge. I say ten bucks the next guy says eleven... so on and so on. Once the consumer decides who is going to do the work the price is set. Now.... beat your own time for doing the work. If you run over your allotted time, well, that's poor planning on your part. If you can come in under your projected time... well.. "Home Run". Now the customer has only one option from you. If you say the job will take 5 hours. No way, no how, will the customer get their car back in 4 hours. I may have lost a few jobs over the years because of this policy but I've never EVER had to back pedal on one since. May not work for everyone... but it sure does for me. -

One More Busted Knuckle It's the grease, the grime, the clank of a loose rod bearing, or the snap of a fuse that is familiar to anyone who has ever worked on cars. But, along with the noises and smells of the business there are the scrapes and bruises. Working with machinery, moving parts, and numerous sharp objects there's bound to be a few personal injuries involved. Sometimes I can go an entire week without cutting myself or jamming a finger, but then there are those days… the ones where I have to make a mad dash for the First Aid kit. It just adds to the challenges of the job. Have you ever been complacent while working on a car? You know... just lost your concentration for a moment and did something stupid? I know I have. Like the time I hit the trigger on my new high torque air ratchet with the wrong size socket on it. As the ratchet spun, it took me for an unsuspected ride as it slammed up against the car's engine with a couple of my fingers jammed in between. Man, did that hurt! Good thing for rubber gloves, especially the black neoprene ones. (They don't show blood stains as well, and they tend to hold everything together long enough for you to find the First Aid kit and check for damage.) Like a lot of technicians I've got scars, a couple of broken fingers, and a few swollen joints from working on cars all these years. The older I get the more war wounds I seem to collect. "With age comes wisdom". I sometimes have my doubts about that. I sure feel pretty stupid when I get that next bruised or busted knuckle. Age sure doesn't help with the eye sight, or the knees, oh and don't forget about that aching back! Let's face it, working on cars and trucks is a physically demanding job, as well as a mental workout. I can remember a time back in my youth, when I would bench press a tranny up into the car while lying on a dirt floor. I don't think I'll try that these days. I've grown out of that macho style of auto repair. You know, always trying to prove I can tackle a big job by myself. (Hint,hint… for you younger techs) I'm much older now. Proving my testosterone level by doing some Herculean feat, which only ends up with another scar for my efforts, is no way to end the day. Sure wish I would have understood that back then, might have saved me from a few bumps and bruises. You could say; "Chalk it up to experience" or "Been there-done that-Know better now", kind of thinking. With blisters, sores, aching muscles,dirt under the finger nails, and the ever present grease stains deep in the grooves of my palms, there's no denying what I do for a living.. Yep, that's right… I'm a mechanic. Those bumps and bruises are all part of the job, even though I don't remember anyone I ever trained with mentioning that. (Should've been a course in tech school on proper bandage installation and application; after what I've been through, I could ace that class.) Like a lot of techs, I only get paid for what I accomplish. Even if this means putting on an extra bandage, and if capable...get back to work. On one particular day I was changing the U-joints on a truck. The customer had dropped it off early that morning, and I said I could have it done by lunchtime. The joints weren't that hard to change, but getting the drive shaft off was. Three of the four rear yoke bolts came off with no problem, but the fourth one... I wasn't so lucky. The wrench slipped off, and with the force I had on the bolt my whole arm shot skyward. A sliver of MIG welding wire was still on the joint where the rear yoke housing is welded to the actual drive shaft pipe fromthe factory. This made for a perfect slice and dice on my forearm as it passed by. By the time the customer picked the truck up that afternoon I had most of my forearm wrapped up. "What ya do to that arm?" he asked. I told him how it happened in all the gory details. I'd like to say he was concerned. He was… just not with my arm. Oh heck no... He was more concerned with his truck. "So you still got the U-joints changed?" he said with a questioning gesture. Yea, thanks for caring, Mr. Customer… I appreciate your thoughts and concerns. Trucks fine, U-joints are fine, I'm fine… life goes on…. Ok, it wasn't that big of a deal...minor cut... no biggie. (My wife just rolls her eyes when I come home with a new bandage on. I think she enjoys tormenting me, while she cleans up my newest altercation with an inanimate object. Gee… Lucky me....). The customer wanted to make sure I removed that hunk of MIG wire, so that no one else would get hurt in the future. Oh don't worry, I did, and I'll have to admit, I removed that little piece of wire as if I had a personal vendetta against it ... Yea, it ain't going to do that to anyone else... EVER again! Outside the daily workings of the shop I'm asked to speak at different functions, or invited to some event where I'll be shaking a few hands. I used to worry about the roughness of my hands, especially when I was in a room of businessmen and women who had no concept of manual labor work in their daily vocations. It was a concern of mine, andat times maybe even a bit embarrassing. But, you know, I've come to realize, I should be proud of what I do, and those scars and callouses I've collected throughout my working years are like my own personal business card. It's who I am... it's what I am...it's the way I am… a mechanic. I'm proud of what I do… we all should be proud of what we do. There aren't a lotof people who can do this job. Putting your arm into a blind or tight spot,while trying to turn a bolt or nut with nothing more than their fingertips, isn't for everyone. As a technician you do it, and don't even think about that sharp jagged piece of metal you're wedged up against... you just do it anyway. Even with a few extra scrapes and scars I'm still going back to this job tomorrow. I don't plan on gouging a test light into my hand while reaching down into an engine bay, but you know… it'll happen... maybe not today, but it will. Best of luck to all the ratchet spinnin', wrench turnin', hardworking techs out there. Stay safe... work smart... and keep the First Aid kit well stocked. There's always tomorrow, and tomorrow is just one more busted knuckle away. View full article

-

One More Busted Knuckle It's the grease, the grime, the clank of a loose rod bearing, or the snap of a fuse that is familiar to anyone who has ever worked on cars. But, along with the noises and smells of the business there are the scrapes and bruises. Working with machinery, moving parts, and numerous sharp objects there's bound to be a few personal injuries involved. Sometimes I can go an entire week without cutting myself or jamming a finger, but then there are those days… the ones where I have to make a mad dash for the First Aid kit. It just adds to the challenges of the job. Have you ever been complacent while working on a car? You know... just lost your concentration for a moment and did something stupid? I know I have. Like the time I hit the trigger on my new high torque air ratchet with the wrong size socket on it. As the ratchet spun, it took me for an unsuspected ride as it slammed up against the car's engine with a couple of my fingers jammed in between. Man, did that hurt! Good thing for rubber gloves, especially the black neoprene ones. (They don't show blood stains as well, and they tend to hold everything together long enough for you to find the First Aid kit and check for damage.) Like a lot of technicians I've got scars, a couple of broken fingers, and a few swollen joints from working on cars all these years. The older I get the more war wounds I seem to collect. "With age comes wisdom". I sometimes have my doubts about that. I sure feel pretty stupid when I get that next bruised or busted knuckle. Age sure doesn't help with the eye sight, or the knees, oh and don't forget about that aching back! Let's face it, working on cars and trucks is a physically demanding job, as well as a mental workout. I can remember a time back in my youth, when I would bench press a tranny up into the car while lying on a dirt floor. I don't think I'll try that these days. I've grown out of that macho style of auto repair. You know, always trying to prove I can tackle a big job by myself. (Hint,hint… for you younger techs) I'm much older now. Proving my testosterone level by doing some Herculean feat, which only ends up with another scar for my efforts, is no way to end the day. Sure wish I would have understood that back then, might have saved me from a few bumps and bruises. You could say; "Chalk it up to experience" or "Been there-done that-Know better now", kind of thinking. With blisters, sores, aching muscles,dirt under the finger nails, and the ever present grease stains deep in the grooves of my palms, there's no denying what I do for a living.. Yep, that's right… I'm a mechanic. Those bumps and bruises are all part of the job, even though I don't remember anyone I ever trained with mentioning that. (Should've been a course in tech school on proper bandage installation and application; after what I've been through, I could ace that class.) Like a lot of techs, I only get paid for what I accomplish. Even if this means putting on an extra bandage, and if capable...get back to work. On one particular day I was changing the U-joints on a truck. The customer had dropped it off early that morning, and I said I could have it done by lunchtime. The joints weren't that hard to change, but getting the drive shaft off was. Three of the four rear yoke bolts came off with no problem, but the fourth one... I wasn't so lucky. The wrench slipped off, and with the force I had on the bolt my whole arm shot skyward. A sliver of MIG welding wire was still on the joint where the rear yoke housing is welded to the actual drive shaft pipe fromthe factory. This made for a perfect slice and dice on my forearm as it passed by. By the time the customer picked the truck up that afternoon I had most of my forearm wrapped up. "What ya do to that arm?" he asked. I told him how it happened in all the gory details. I'd like to say he was concerned. He was… just not with my arm. Oh heck no... He was more concerned with his truck. "So you still got the U-joints changed?" he said with a questioning gesture. Yea, thanks for caring, Mr. Customer… I appreciate your thoughts and concerns. Trucks fine, U-joints are fine, I'm fine… life goes on…. Ok, it wasn't that big of a deal...minor cut... no biggie. (My wife just rolls her eyes when I come home with a new bandage on. I think she enjoys tormenting me, while she cleans up my newest altercation with an inanimate object. Gee… Lucky me....). The customer wanted to make sure I removed that hunk of MIG wire, so that no one else would get hurt in the future. Oh don't worry, I did, and I'll have to admit, I removed that little piece of wire as if I had a personal vendetta against it ... Yea, it ain't going to do that to anyone else... EVER again! Outside the daily workings of the shop I'm asked to speak at different functions, or invited to some event where I'll be shaking a few hands. I used to worry about the roughness of my hands, especially when I was in a room of businessmen and women who had no concept of manual labor work in their daily vocations. It was a concern of mine, andat times maybe even a bit embarrassing. But, you know, I've come to realize, I should be proud of what I do, and those scars and callouses I've collected throughout my working years are like my own personal business card. It's who I am... it's what I am...it's the way I am… a mechanic. I'm proud of what I do… we all should be proud of what we do. There aren't a lotof people who can do this job. Putting your arm into a blind or tight spot,while trying to turn a bolt or nut with nothing more than their fingertips, isn't for everyone. As a technician you do it, and don't even think about that sharp jagged piece of metal you're wedged up against... you just do it anyway. Even with a few extra scrapes and scars I'm still going back to this job tomorrow. I don't plan on gouging a test light into my hand while reaching down into an engine bay, but you know… it'll happen... maybe not today, but it will. Best of luck to all the ratchet spinnin', wrench turnin', hardworking techs out there. Stay safe... work smart... and keep the First Aid kit well stocked. There's always tomorrow, and tomorrow is just one more busted knuckle away.

-

That line about the economy was my way of saying, "As different things are... the more they remain the same." I wouldn't doubt that the economic and government concerns will be no different in the far reaching future. But, my main "theme" was to show how what we thought was sci-fi back in the 30's and thru the 50's is now real...actual..and more or less everyday things to you and I. The story was all about concepts... ideas... and what a "modern" tech may experience. thanx for the comments Joe... ur the best.

-

I'm waiting for the self driving cars on the highway. There's going to be such a crazy world with a mix of old tech cars with self drive cars on the road together. I can't see how a car is going to avoid a crash when somebody in a 68 Mustang plows down the road at 90 and smacks right into them. I don't think the technology is all there... yet.

-

Sci-Fi or Our Future Reality? The year is 2168. Bob is on his way to pick up his car from the repair shop. It didn't need much, just a new phase shifter for his low orbit cruise control. His buddy, Tom was happy to give him a ride to pick it up. His new car is equipped with the new ½ light speed option, which really speeds up his travel time. As they arrive at the service center, Tom says, "So this is where you get your car serviced?" "Yea, sure is," Bob tells his buddy, "I've been coming here for quite some time." With the economy just now getting back on its feet, and a good amount of nostalgia in all the advertisements, most of the car manufacturers have decided to use retro names for their new models, like Camaro, Thunderbird, Road Runner,Mustang, just to give them more of that old muscle car feel from the mid-21thcentury. For years there's been a hold on how much power the government would allow in a private car, but that's all changed now. With the restrictions lifted on the TTP (Total Thrust Propulsion) every car geek out there is going for these super-fast cars with the classic names, and with a few modifications you can just about make it to full light speed. (Like Tom's car.) Pretty cool stuff for the modern hot rodders. Nobody drives on the old concrete and black top highways anymore. All those early muscle cars have been moth balled into sealed rooms for public view and private collections. So, there's no need to maintain the road systems anymore. Everyone uses the transportation lanes at different altitudes rather than down on the old, dilapidated highways. Gravity is still a factor, but not so much for the transportation industry. Since gravitational balance was obtained about 100 years ago, there's really no need for ground travel options on modern cars. (Tires are such a waste of natural resources anyway.) Oh sure, there's still a lot of people out there driving around with old mag-lift technology, but they can't get any higher than the second level on the transportation lanes. They're just too slow and unpredictable. (Tom and Bob both agree that people really should look at getting newer cars; you know…,something with a jump speed for interstellar travel.) "Gotta go Tom, thanks for the ride," Bob says to his buddy, as he pulls out of the service center parking area. "I'm heading to Parizolas-1 in the Pexar galaxy to see my family." Bob flips on the navigational system, programs his destination, applies the auto directional pilot controls, and sits back for a relaxing ride across the space highway. It will have him at his parents' house in no time. Tom decided to stick around a bit and check out the service facility. He waved goodbye to his buddy, and watched him gain altitude towards the outer orbit on ramp for the IGS (Inter-galacticSpace-way). After Bob was out of sightTom took a stroll through the service center, watching all the displays change images, and listened to the specials being offered. He peered through the glass enclosures at the cars entering and leaving the service bays, and watched the technicians make adjustments to the programs. The service bays are completely automated. Robots handle all the fluid changes and major work, but there's still a technician in the bay to manage everything that is going on. As a car enters the service bay the technician starts scanning the car from the front to the rear. In just a few seconds he can see the results on his view screen and knows just what needs to be taking care of. Most of the on-board systems in the car will repair things themselves, but there are occasions when the nano-bots in the car's matrix overlook something. That's where the full scan at the repair shop is needed. The technician orders the needed repair parts from the storeroom and assigns the appropriate task robot to make the repairs. While Bob could have waited for the repairs to be made on his Camaro, he thought he would save time by having the car deliver itself to the repair shop. The technician at the service center can send your car back to you, or like Bob, you can pick it up yourself. You can also schedule the next service based on the information you provided. You won't even know your car is at the shop. It can program itself to arrive at the service center when it's the most convenient for you. But, don't worry… the car will inform you of its travels as soon as you enter the car the next time. These days, cars and people are almost on the same level; it knows your moods, it knows where you go, when you need transportation, and can perform most of these tasks with nothing more than a thought from you. Tom was really impressed with the shop. It's a lot nicer than where he's been going. He decided to enter his cars' diagnostic log chip into the shop's memory unit, so his car would automatically use this shop instead of his last one. All the service records are automatically sent to the new facility, and any components on order will be shipped directly to the new shop, too. As Tom gets ready to leave, he had to show off his hopped-up hot rod for the service techs. He hits the override control and plants the throttle to the wide open position. With a shower of cosmic particles he speeds off into the distance. Sounds farfetched, doesn't it? It's not our reality; it's science fiction to you and me. But imagine what it would have been like to explain to someone from the early 20th century about a car from 2012? They probably would've had you committed, or something worse than that. That doesn't mean they didn't have their far into the future thinkers, they certainly did. In fact they had their own visions of the future too, from futuristic movies like; Buck Rogers and space travel to Mars, to stories about a man landing on the moon. Why, they even had Dick Tracy in the comic strips, who could talk to his wrist watch with a 2 way video screen. Now take a moment and jump back to 2012 … think about it for a second…most of those early ideas have already been accomplished. So, if you would have told someone from the early 20th century that by 2012 your car could not only avoid getting into a crash, it could park itself, and could be started without you even being near it, do you think they would have believed you? It's simply amazing how those thoughts and ideas from the turn of the century end up being today's technology, but I'll bet in 2168 they'll say the same thing about our "historic" tries at technology too. So, for all you far out into space thinkers, keep looking over the horizon because there's a good chance what we think of as automotive fantasy today will become common place in the future. Look out year 2168... we're coming your way! ! ! View full article

-

Sci-Fi or Our Future Reality? The year is 2168. Bob is on his way to pick up his car from the repair shop. It didn't need much, just a new phase shifter for his low orbit cruise control. His buddy, Tom was happy to give him a ride to pick it up. His new car is equipped with the new ½ light speed option, which really speeds up his travel time. As they arrive at the service center, Tom says, "So this is where you get your car serviced?" "Yea, sure is," Bob tells his buddy, "I've been coming here for quite some time." With the economy just now getting back on its feet, and a good amount of nostalgia in all the advertisements, most of the car manufacturers have decided to use retro names for their new models, like Camaro, Thunderbird, Road Runner,Mustang, just to give them more of that old muscle car feel from the mid-21thcentury. For years there's been a hold on how much power the government would allow in a private car, but that's all changed now. With the restrictions lifted on the TTP (Total Thrust Propulsion) every car geek out there is going for these super-fast cars with the classic names, and with a few modifications you can just about make it to full light speed. (Like Tom's car.) Pretty cool stuff for the modern hot rodders. Nobody drives on the old concrete and black top highways anymore. All those early muscle cars have been moth balled into sealed rooms for public view and private collections. So, there's no need to maintain the road systems anymore. Everyone uses the transportation lanes at different altitudes rather than down on the old, dilapidated highways. Gravity is still a factor, but not so much for the transportation industry. Since gravitational balance was obtained about 100 years ago, there's really no need for ground travel options on modern cars. (Tires are such a waste of natural resources anyway.) Oh sure, there's still a lot of people out there driving around with old mag-lift technology, but they can't get any higher than the second level on the transportation lanes. They're just too slow and unpredictable. (Tom and Bob both agree that people really should look at getting newer cars; you know…,something with a jump speed for interstellar travel.) "Gotta go Tom, thanks for the ride," Bob says to his buddy, as he pulls out of the service center parking area. "I'm heading to Parizolas-1 in the Pexar galaxy to see my family." Bob flips on the navigational system, programs his destination, applies the auto directional pilot controls, and sits back for a relaxing ride across the space highway. It will have him at his parents' house in no time. Tom decided to stick around a bit and check out the service facility. He waved goodbye to his buddy, and watched him gain altitude towards the outer orbit on ramp for the IGS (Inter-galacticSpace-way). After Bob was out of sightTom took a stroll through the service center, watching all the displays change images, and listened to the specials being offered. He peered through the glass enclosures at the cars entering and leaving the service bays, and watched the technicians make adjustments to the programs. The service bays are completely automated. Robots handle all the fluid changes and major work, but there's still a technician in the bay to manage everything that is going on. As a car enters the service bay the technician starts scanning the car from the front to the rear. In just a few seconds he can see the results on his view screen and knows just what needs to be taking care of. Most of the on-board systems in the car will repair things themselves, but there are occasions when the nano-bots in the car's matrix overlook something. That's where the full scan at the repair shop is needed. The technician orders the needed repair parts from the storeroom and assigns the appropriate task robot to make the repairs. While Bob could have waited for the repairs to be made on his Camaro, he thought he would save time by having the car deliver itself to the repair shop. The technician at the service center can send your car back to you, or like Bob, you can pick it up yourself. You can also schedule the next service based on the information you provided. You won't even know your car is at the shop. It can program itself to arrive at the service center when it's the most convenient for you. But, don't worry… the car will inform you of its travels as soon as you enter the car the next time. These days, cars and people are almost on the same level; it knows your moods, it knows where you go, when you need transportation, and can perform most of these tasks with nothing more than a thought from you. Tom was really impressed with the shop. It's a lot nicer than where he's been going. He decided to enter his cars' diagnostic log chip into the shop's memory unit, so his car would automatically use this shop instead of his last one. All the service records are automatically sent to the new facility, and any components on order will be shipped directly to the new shop, too. As Tom gets ready to leave, he had to show off his hopped-up hot rod for the service techs. He hits the override control and plants the throttle to the wide open position. With a shower of cosmic particles he speeds off into the distance. Sounds farfetched, doesn't it? It's not our reality; it's science fiction to you and me. But imagine what it would have been like to explain to someone from the early 20th century about a car from 2012? They probably would've had you committed, or something worse than that. That doesn't mean they didn't have their far into the future thinkers, they certainly did. In fact they had their own visions of the future too, from futuristic movies like; Buck Rogers and space travel to Mars, to stories about a man landing on the moon. Why, they even had Dick Tracy in the comic strips, who could talk to his wrist watch with a 2 way video screen. Now take a moment and jump back to 2012 … think about it for a second…most of those early ideas have already been accomplished. So, if you would have told someone from the early 20th century that by 2012 your car could not only avoid getting into a crash, it could park itself, and could be started without you even being near it, do you think they would have believed you? It's simply amazing how those thoughts and ideas from the turn of the century end up being today's technology, but I'll bet in 2168 they'll say the same thing about our "historic" tries at technology too. So, for all you far out into space thinkers, keep looking over the horizon because there's a good chance what we think of as automotive fantasy today will become common place in the future. Look out year 2168... we're coming your way! ! !

-

Great article. and, in some cases... it does turn out to be "Well, I can't afford "not" to do it, then sometimes... it still doesn't work. Just depends on the way the customer is looking at the problem and/or their budget.

-

She's a little high strung... LOL. Gets pretty excited when there's an unfamiliar person around or a different dog. Goes into her "Cujo" mode... barks and snarls...LOUD... but the training is helping. She's totally harmless but you know how it is... big dogs, big barks... it'll make ya back up. The most surprising thing is... frisbees... the dog LOVES frisbees... she'll catch it no matter how far you throw it or how high. She'll actually stop, look up, and follow it with her eyes. And I'm not kidding... as long as her legs will get her there she'll catch it. Started introducing her to frisbees at about a month old. Unbelievable... the dog trainer can't even believe it. Oh, well... enough on that. Again... as always, I really appreciate your input to the stories... Your insight is more than just a casual glance at the story... you get it... you understand them... and for that I tip my hat to you... well, in this case maybe a frisbee...that is if I can get it from the dog. LOL

-

New Dog, Old Tricks "Sit! Sable, sit", I tell the family's new German Shepherd pup. When she sits, she gets a treat. "Good dog, Sable... good dog." She's only 8 months old, but she is already turning out to be a great dog for the family. We've decided to make sure she has the proper training, and not learn any bad habits from us "novice pet parents". Instead we are taking her to training classes once a week with an expert dog handler/trainer. We're hoping to have Sable trained as a "companion dog" after all the training is finished. Although, really... the training never ends. Every day there's a new challenge and a new skill to learn. At the training session all the dog handlers (Oops, I mean pet parents) are standing in a straight line waiting for our next instructions. I've got the leash in hand, the dog at heel position, and I'm intent on listening for every instruction the trainer tells us. It reminded me of those early days when I first started in the repair business. There I was a naive, still green behind the ears young tech thinking he knew it all, only to be told to go sit. I spent hours upon hours walking alongside another tech, observing how he solved a problem or made use of a certain tool. I guess in a way I was just like the pup... I probably looked a lot like the dog; eager to see what was to be next, well… OK, everything except for the tail wag and the tongue hanging out, of course. It took some time to learn this trade, but I eventually caught on how to diagnose the problems and make the repairs myself. But, just like Sable, I learn something new each and every day. On occasions I'll have an intern in my shop doing their "hands-on" training. They're just as eager to learn, watch and understand what I'm doing, just like I was back then. They want to know how to use the variety of tools, scanners, and equipment that most of us who have been in the business for years take for granted. I have to stop and remind myself, "These interns don't know those old school tricks. They don't know what I know... I'm here to teach those things that can't be taught out of a book." There was this one intern I had who really wanted to be involved with every repair in the shop. He was a pretty sharp kid, he had already been through several class trainings, and did some hands on at another shop. But, he still had a lot to learn. His enthusiasm was contagious to say the least, which, by the way, made it a lot easier to let him be more involved with each and every repair. One day, shortly after he started, we had a mid-90's GM come in the shop. I pulled the car into the service bay where he was waiting. Then I jumped out and told him, "I forgot the work order. I'll run up front and get it. Pop the hood open, would ya. I'll be right back". When I came back, there he was kneeling in front of the car peering thru the grill with a screwdriver, trying to pry the hood open. "What the heck are you doing?" I barked at him. "The hood wouldn't open, so I was going to "jimmy" the latch." I just stood there holding my head with my hand, while looking at the floor, shaking my head back and forth. "Here, let me show you something," I told him. I reached in and pulled the latch one more time, then went out to the hood and lightly popped the hood with my fist just above the latch. "Pop" goes the hood. He stood there with a surprised look on his face. "How did ya do that?" he asked. "Oh, a lot of these stick like that; all you have to do is give it a quick little pop and it springs open," I told him. I didn't realize it at the time, but I just showed this young wrench hand a little something most techs already knew, and for the most part took for granted. For him, this was a revelation. "You can put that screwdriver away, Bud," I told him. A few weeks later I needed an 8mm bolt for a project, and my intern... as always... was standing right next to me. "Go over to the miscellaneous bolt bin and find me an 8mm with fine thread, if you please. "Going to get it right this second, Chief," He said with a grin, and off in a flash went my energetic intern. He seemed to be gone for quite some time, and I was getting a little concerned. It shouldn't take that long to find a bolt. I went back to the storage room where we kept the bolt bin, and there he was sorting bolts, still trying to find the right one. "What's the problem?" I asked "I'm not sure if this one is 8mm… or this one," he answered. "Why don't you go over to your tool box and grab your 8mm box end wrench, and come back here." With that he shot out the door and was back in just a second. He came into the storage room at full speed, and then stopped dead in his tracks just in front of me holding his wrench in his outstretched arms. I handed him a bolt, "Here try this bolt with your wrench." As I expected, he went right for the hex head and tried to fit the wrench to it. "No, no... Use the box end, and see if it fits the actual bolt. Not the part you turn the bolt with, I'm after the actual bolt size." He caught on pretty fast, even though he still had a bit of a puzzled look on his face. He slid the box end of the wrench over the bolt for a perfect fit. "See, there ya go... that's an 8mm bolt for sure," I said with a grin. The smile he had on his face was priceless. Here again was another example of a new tech learning an old trick. Eventually my young intern became quite a tech in his own right. After graduating from his tech class, he got a job at a large shop in his home town. I'll bet even to this day he is probably learning more old tricks, and someday he'll be the guy showing them to the next young tech who comes along. In the meantime, my handling skills and dog training continue. I've got a lot to learn myself. Just like in my chosen trade the skills you learn are equal to the amount of effort you put into it. I'm kind of the old dog these days, but I'm not afraid to learn a few new tricks myself. But, I'll be sure to pass on my "old tricks of the trade" to the next tech in line. Oh well, back to dog training... "Sit, Sable, Sit!"... Good dog... good dog... Now if I could only teach her to fetch me that 8mm wrench.... View full article

-

New Dog, Old Tricks "Sit! Sable, sit", I tell the family's new German Shepherd pup. When she sits, she gets a treat. "Good dog, Sable... good dog." She's only 8 months old, but she is already turning out to be a great dog for the family. We've decided to make sure she has the proper training, and not learn any bad habits from us "novice pet parents". Instead we are taking her to training classes once a week with an expert dog handler/trainer. We're hoping to have Sable trained as a "companion dog" after all the training is finished. Although, really... the training never ends. Every day there's a new challenge and a new skill to learn. At the training session all the dog handlers (Oops, I mean pet parents) are standing in a straight line waiting for our next instructions. I've got the leash in hand, the dog at heel position, and I'm intent on listening for every instruction the trainer tells us. It reminded me of those early days when I first started in the repair business. There I was a naive, still green behind the ears young tech thinking he knew it all, only to be told to go sit. I spent hours upon hours walking alongside another tech, observing how he solved a problem or made use of a certain tool. I guess in a way I was just like the pup... I probably looked a lot like the dog; eager to see what was to be next, well… OK, everything except for the tail wag and the tongue hanging out, of course. It took some time to learn this trade, but I eventually caught on how to diagnose the problems and make the repairs myself. But, just like Sable, I learn something new each and every day. On occasions I'll have an intern in my shop doing their "hands-on" training. They're just as eager to learn, watch and understand what I'm doing, just like I was back then. They want to know how to use the variety of tools, scanners, and equipment that most of us who have been in the business for years take for granted. I have to stop and remind myself, "These interns don't know those old school tricks. They don't know what I know... I'm here to teach those things that can't be taught out of a book." There was this one intern I had who really wanted to be involved with every repair in the shop. He was a pretty sharp kid, he had already been through several class trainings, and did some hands on at another shop. But, he still had a lot to learn. His enthusiasm was contagious to say the least, which, by the way, made it a lot easier to let him be more involved with each and every repair. One day, shortly after he started, we had a mid-90's GM come in the shop. I pulled the car into the service bay where he was waiting. Then I jumped out and told him, "I forgot the work order. I'll run up front and get it. Pop the hood open, would ya. I'll be right back". When I came back, there he was kneeling in front of the car peering thru the grill with a screwdriver, trying to pry the hood open. "What the heck are you doing?" I barked at him. "The hood wouldn't open, so I was going to "jimmy" the latch." I just stood there holding my head with my hand, while looking at the floor, shaking my head back and forth. "Here, let me show you something," I told him. I reached in and pulled the latch one more time, then went out to the hood and lightly popped the hood with my fist just above the latch. "Pop" goes the hood. He stood there with a surprised look on his face. "How did ya do that?" he asked. "Oh, a lot of these stick like that; all you have to do is give it a quick little pop and it springs open," I told him. I didn't realize it at the time, but I just showed this young wrench hand a little something most techs already knew, and for the most part took for granted. For him, this was a revelation. "You can put that screwdriver away, Bud," I told him. A few weeks later I needed an 8mm bolt for a project, and my intern... as always... was standing right next to me. "Go over to the miscellaneous bolt bin and find me an 8mm with fine thread, if you please. "Going to get it right this second, Chief," He said with a grin, and off in a flash went my energetic intern. He seemed to be gone for quite some time, and I was getting a little concerned. It shouldn't take that long to find a bolt. I went back to the storage room where we kept the bolt bin, and there he was sorting bolts, still trying to find the right one. "What's the problem?" I asked "I'm not sure if this one is 8mm… or this one," he answered. "Why don't you go over to your tool box and grab your 8mm box end wrench, and come back here." With that he shot out the door and was back in just a second. He came into the storage room at full speed, and then stopped dead in his tracks just in front of me holding his wrench in his outstretched arms. I handed him a bolt, "Here try this bolt with your wrench." As I expected, he went right for the hex head and tried to fit the wrench to it. "No, no... Use the box end, and see if it fits the actual bolt. Not the part you turn the bolt with, I'm after the actual bolt size." He caught on pretty fast, even though he still had a bit of a puzzled look on his face. He slid the box end of the wrench over the bolt for a perfect fit. "See, there ya go... that's an 8mm bolt for sure," I said with a grin. The smile he had on his face was priceless. Here again was another example of a new tech learning an old trick. Eventually my young intern became quite a tech in his own right. After graduating from his tech class, he got a job at a large shop in his home town. I'll bet even to this day he is probably learning more old tricks, and someday he'll be the guy showing them to the next young tech who comes along. In the meantime, my handling skills and dog training continue. I've got a lot to learn myself. Just like in my chosen trade the skills you learn are equal to the amount of effort you put into it. I'm kind of the old dog these days, but I'm not afraid to learn a few new tricks myself. But, I'll be sure to pass on my "old tricks of the trade" to the next tech in line. Oh well, back to dog training... "Sit, Sable, Sit!"... Good dog... good dog... Now if I could only teach her to fetch me that 8mm wrench....